|

Grade |

Remanence (Br) |

Coercive Force (bHc) |

Intrisic Coercive Force (Hcj) |

Max Energy Product (BH)max |

Working Temp (L/D=0.7) |

||||

| KGS | T | KOe | KA/m | KOe | KA/m | MGOe | KJ/m? | ℃ | |

| N35 | 11.8-12.4 | 1.18-1.24 | ≥10.5 | ≥835 | ≥12 | ≥955 | ≥33 | ≥263 | ≤80 |

| N38 | 12.3-12.8 | 1.23-1.28 | ≥10.8 | ≥859 | ≥12 | ≥955 | ≥36 | ≥286 | ≤80 |

| N40 | 12.6-13.2 | 1.26-1.32 | ≥10.8 | ≥859 | ≥12 | ≥955 | 38-41 | 302-326 | ≤80 |

| N42 | 12.8-13.4 | 1.28-1.34 | ≥10.8 | ≥859 | ≥12 | ≥955 | 40-44 | 318-350 | ≤80 |

| N45 | 13.2-13.8 | 1.32-1.38 | ≥11.0 | ≥875 | ≥12 | ≥955 | 43-47 | 342-374 | ≤80 |

| N48 | 13.6-14.1 | 1.36-1.41 | ≥11.2 | ≥891 | ≥12 | ≥955 | 45-49 | 358-390 | ≤80 |

| N50 | 13.9-14.6 | 1.39-1.46 | ≥11.2 | ≥891 | ≥12 | ≥955 | 47-51 | 374-405 | ≤80 |

| N52 | 14.2-14.6 | 1.42-1.46 | ≥10.2 | ≥812 | ≥11 | ≥875 | 48-53 | 390-422 | ≤80 |

| 38M | 12.3-12.8 | 1.23-1.28 | ≥11.5 | ≥915 | ≥14 | ≥1114 | 36-38 | 286-302 | ≤100 |

| 40M | 12.6-13.2 | 1.26-1.32 | ≥11.8 | ≥939 | ≥14 | ≥1114 | 38-41 | 302-326 | ≤100 |

| 42M | 12.8-13.4 | 1.28-1.34 | ≥12.0 | ≥955 | ≥14 | ≥1114 | 40-43 | 318-342 | ≤100 |

| 45M | 13.2-13.8 | 1.32-1.38 | ≥12.2 | ≥971 | ≥14 | ≥1114 | 43-46 | 342-366 | ≤100 |

| 48M | 13.6-14.0 | 1.36-1.40 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 45-49 | 358-390 | ≤100 |

| 50M | 13.9-14.3 | 1.39-1.43 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 47-51 | 374-405 | ≤100 |

| 35H | 11.7-12.4 | 1.17-1.24 | ≥10.8 | ≥859 | ≥17 | ≥1353 | 33-37 | 263-295 | ≤120 |

| 38H | 12.3-12.8 | 1.23-1.28 | ≥11.5 | ≥915 | ≥17 | ≥1353 | 36-40 | 286-318 | ≤120 |

| 40H | 12.6-13.2 | 1.26-1.32 | ≥11.8 | ≥939 | ≥17 | ≥1353 | 38-41 | 302-326 | ≤120 |

| 42H | 12.8-13.4 | 1.28-1.34 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 40-43 | 318-342 | ≤120 |

| 45H | 13.2-13.8 | 1.32-1.38 | ≥12.2 | ≥971 | ≥17 | ≥1353 | 43-46 | 342-366 | ≤120 |

| 48H | 13.6-14.2 | 1.36-1.42 | ≥12.8 | ≥1019 | ≥17 | ≥1274 | 45-48 | 358-382 | ≤120 |

| 33SH | 11.4-12.0 | 1.14-1.20 | ≥10.5 | ≥835 | ≥20 | ≥1592 | ≥31 | ≥247 | ≤150 |

| 35SH | 11.7-12.5 | 1.17-1.25 | ≥10.8 | ≥859 | ≥20 | ≥1592 | ≥33 | ≥263 | ≤150 |

| 38SH | 12.2-12.7 | 1.22-1.27 | ≥11.3 | ≥899 | ≥20 | ≥1592 | 36-39 | 286-310 | ≤150 |

| 40SH | 12.4-13.0 | 1.24-1.30 | ≥11.8 | ≥939 | ≥20 | ≥1592 | 38-41 | 302-326 | ≤150 |

| 42SH | 12.8-13.6 | 1.28-1.36 | ≥12.0 | ≥955 | ≥20 | ≥1592 | 39-43 | 310-342 | ≤150 |

| 45SH | 13.2-13.7 | 1.32-1.37 | ≥12.2 | ≥971 | ≥20 | ≥1592 | 43-46 | 342-366 | ≤150 |

| 48SH | 13.6-14.1 | 1.36-1.41 | ≥12.8 | ≥1019 | ≥20 | ≥1592 | 45-48 | 358-382 | ≤150 |

| 30UH | 10.8-11.0 | 1.08-1.10 | ≥9.5 | ≥756 | ≥25 | ≥1990 | 28-31 | 223-247 | ≤180 |

| 33UH | 11.3-11.7 | 1.13-1.17 | ≥9.8 | ≥780 | ≥25 | ≥1990 | 31-34 | 247-270 | ≤180 |

| 35UH | 11.7-12.1 | 1.17-1.21 | ≥10.5 | ≥835 | ≥25 | ≥1990 | 33-36 | 263-286 | ≤180 |

| 38UH | 12.2-12.7 | 1.22-1.27 | ≥11.3 | ≥899 | ≥25 | ≥1990 | 36-39 | 286-310 | ≤180 |

| 40UH | 12.4-13.0 | 1.24-1.30 | ≥11.8 | ≥939 | ≥25 | ≥1990 | 38-41 | 302-326 | ≤180 |

| 30EH | 10.8-11.5 | 1.08-1.15 | ≥10.1 | ≥804 | ≥30 | ≥2388 | 28-31 | 223-247 | ≤200 |

| 32EH | 11.3-12.1 | 1.13-1.21 | ≥10.5 | ≥835 | ≥30 | ≥2388 | 30-33 | 238-263 | ≤200 |

| 35EH | 11.8-12.5 | 1.18-1.25 | ≥11.0 | ≥875 | ≥30 | ≥2388 | 33-35 | 263-278 | ≤200 |

| 38EH | 12.2-12.7 | 1.22-1.27 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 36-39 | 286-310 | ≤200 |

| 40EH | 12.4-13.0 | 1.24-1.30 | ≥11.8 | ≥939 | ≥30 | ≥2388 | 38-41 | 302-326 | ≤200 |

1T=10kGs,1kOe=79.6kA/m,lMGOe=7.96kJ/m3。

The open flux irreversible loss of the testing sample at this temperature≤5%.

Physical Properties of Sintered NdFeB Material

| Items | Parameter Values | Unit |

| Curie Temperature | 310~380 | ℃ |

| Relative Recoil Permeability | 1.02~1.05 | |

| Reversible Temperature Coefficient of Br (20~100℃) | -0.09~-0.13 | %/℃ |

| Reversible Temperature Coefficient of Hcj (20~100℃) | -0.4~-0.7 | %/℃ |

| Density | 7.50~7.70 | g/cm3 |

| Vickers Hardness | 550~700 | |

| Bending Strength | -0.09~-0.13 | MPa |

| 抗拉强度 Tensile Strength | ≥80 | MPa |

| Compressive Strength | 800 ~1050 | MPa |

| Electric Resistivity | 150 | μΩ·cm |

| Thermal Conductivity | 8~10 | W/(M·℃) |

| Coefficient of Thermal Expansion (Parallel to the orientation) | 5 | 10-6/K |

| Coefficient of Thermal Expansion (vertical to the orientation) | -1.5 | 10-6/K |

| Young's Modulus | 150~200 | GPa |

| Specific Heat(20℃~320℃) | 3.0~4.6 | J/(g·k) |

| weight loss(low weight loss products) | ≤2 | mg/cm2 |

Physical Properties & Application to Environment of the Coating

|

Coating Material |

Colour |

Properties |

Environment of Application |

Thickness of Coating layer |

|

Zine |

Blue, Black and rainbow etc |

Compact, Stable and Homogeneous |

With reasonalbe capability of anticorrosion |

6um≤∮≤12 |

|

Nickel-Copper-Nickel |

White and black |

Light and Stable |

Suitable for higher corrosive environment |

15μm≤∮≤30pm |

|

Phosphorization |

Colorless or light gray |

uniform thickness |

short-term anticorrosion |

- |

|

Epoxy |

Black and Gray |

layer with certain luster, insurability |

Suitable for higher corrosive environment |

≥15μm |

|

Parylene |

transparency |

uniform thickness, density pinholes-free and insurability |

Excellent capability of anticorrosion especially for small items |

0.1μm≤∮≤100pm |

|

Ni+Cu+Epoxy |

Black |

Layer with certain luster |

Excellent capability of |

10-30μm |

|

Al+Epoxy |

Black |

Layer with certain luster |

Excellent capability of |

15-35μm |

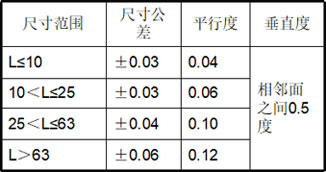

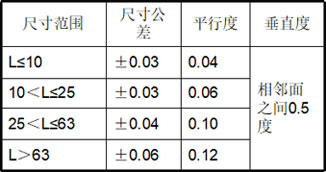

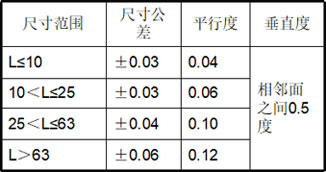

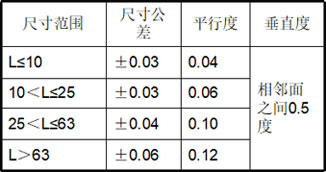

1. Dimension tolerance: length, width, thickness, diameter, etc. (tolerance range is generally not less than + 0.05mm).

2、Form tolerance: vertical degree (0.8°or less), parallel (0.05 mm or less), ovality (0.05 mm or less), concentricity (0.05 mm or less), etc. If the customer has any requirement, it shall follow the standard confirmed after consultation with the customer.

Appearance cleanliness (such as watermark, color), degree of damage (zinc loss, Angle loss, edge knock, black skin), crack, sand hole, knife lines, etc.

1. Magnetized method: According to the requirements of customers.

2. Polarity requirements: Mark according to customer requirements.

3. Packaging materials and methods: general use kraft paper, foam board and carton packaging, special cases using vacuum packaging and shielding packaging, each weighing less than 20 kg. If customer has special requirements for packaging according to customer requirements.

4. Attached documents:

Certificate of approval

销售检测报告

Sales test report (including appearance, size, density, intrinsic magnetic energy, degaussing curve, etc.)

Tell:+86-21-3616-1919*831

Tell:+86-21-3616-1919*831 Fax:+86-21-3616-1005

Fax:+86-21-3616-1005 Email:info@rmag.cn

Email:info@rmag.cn Adress:No.602 Yeji Road,Baoshan Urban Industrial Zone,Shanghai,China.200444

Adress:No.602 Yeji Road,Baoshan Urban Industrial Zone,Shanghai,China.200444